Editors note: A previous version of this story incorrectly said the city, not the port, had purchased the casting basin. That has been corrected.

The Port of Grays Harbor is steaming forward with a project to double the export cargo capability from its terminal in Aberdeen.

Named the straightforward Terminal 4 Expansion and Redevelopment Project, the project, termed “transformational,” will add miles of rail, update infrastructure on the pier itself, and redevelop a former pontoon casting basin on port property into a cargo yard.

“It’ll be the biggest project the port has ever undertaken,” said Kayla Dunlap, the port’s director of government and public affairs, in an interview. “Prior to that, it was the rail improvements in 2011 and 2012. This is double that.”

The project is a partnership with Ag Processing Inc., an Omaha-based agricultural company who is the port’s biggest marine terminal customer, Dunlap said.

“AGP — they’re planning for the future,” Dunlap said. “They know there’s more meal coming, and they want to expand.”

Soy meal, a byproduct of making soybean oil, is AGP’s major export from Grays Harbor — the largest such exporter of soy meal on the West Coast, according to a port news release. AGP exports the meal to countries across the Pacific such as the Philippines, Indonesia and Vietnam where it’s used to feed livestock or for other agribusiness.

“When you crush a bean, which you have to do to get the oil out, about a third is oil and 2/3 is soymeal, protein,” Dunlap said. “Just this month we had three vessels going to Chile — that’s new, that’s a new market.”

While the port is estimating construction costs alone will be $47 million, AGP will be investing $123 million into building the infrastructure at Terminal 4 for rapid loading of meal onto cargo ships bound for ports worldwide, the news release said. The project will also add 80 permanent jobs, according to the news release.

Division of labor

“The port owns everything in this area, and owns the rails as well,” said Port Engineer Kris Koski, who leads the project team.

The project, for the port’s portion, has three main parts, Koski said: the rails, the pier and the cargo yard.

“We’re adding a third loop route through the site,” Koski said. “Rail cars move through it, dump their product, it goes through an underground tunnel onto conveyors onto the ship.”

Unlike Terminal 2 and its iconic silos, imposing themselves on the Aberdeen skyline, Terminal 4 will not have storage facilities — trains will load their cargo directly aboard ship, via new loading infrastructure that AGP will be responsible for building, operating and maintaining. The port will also be adding more rails where trains can wait to the existing rail lines.

“There’s AGP facilities,” Koski said. “Port of Grays Harbor owns the land, AGP owns and builds the equipment.”

The new infrastructure will have three spouts for loading meal onto ships, as opposed to Terminal 2’s single spout, and it will be of a more efficient design involving fewer moving parts, Koski said.

The port is also updating the dock itself, Koski said, which is 1,400-feet long and has enough space for two ships to moor alongside.

“This dock is 50-60 years old. It was built in stages primarily for log export. It still has its original drainage system,” Koski said. “We’re building a new fender system. There’s a fender system now, but it’s an older design.”

The stormwater drainage system will filter rainwater and ensure that runoff doesn’t contain anything outside of the state parameters for such sites, which it inspects regularly.

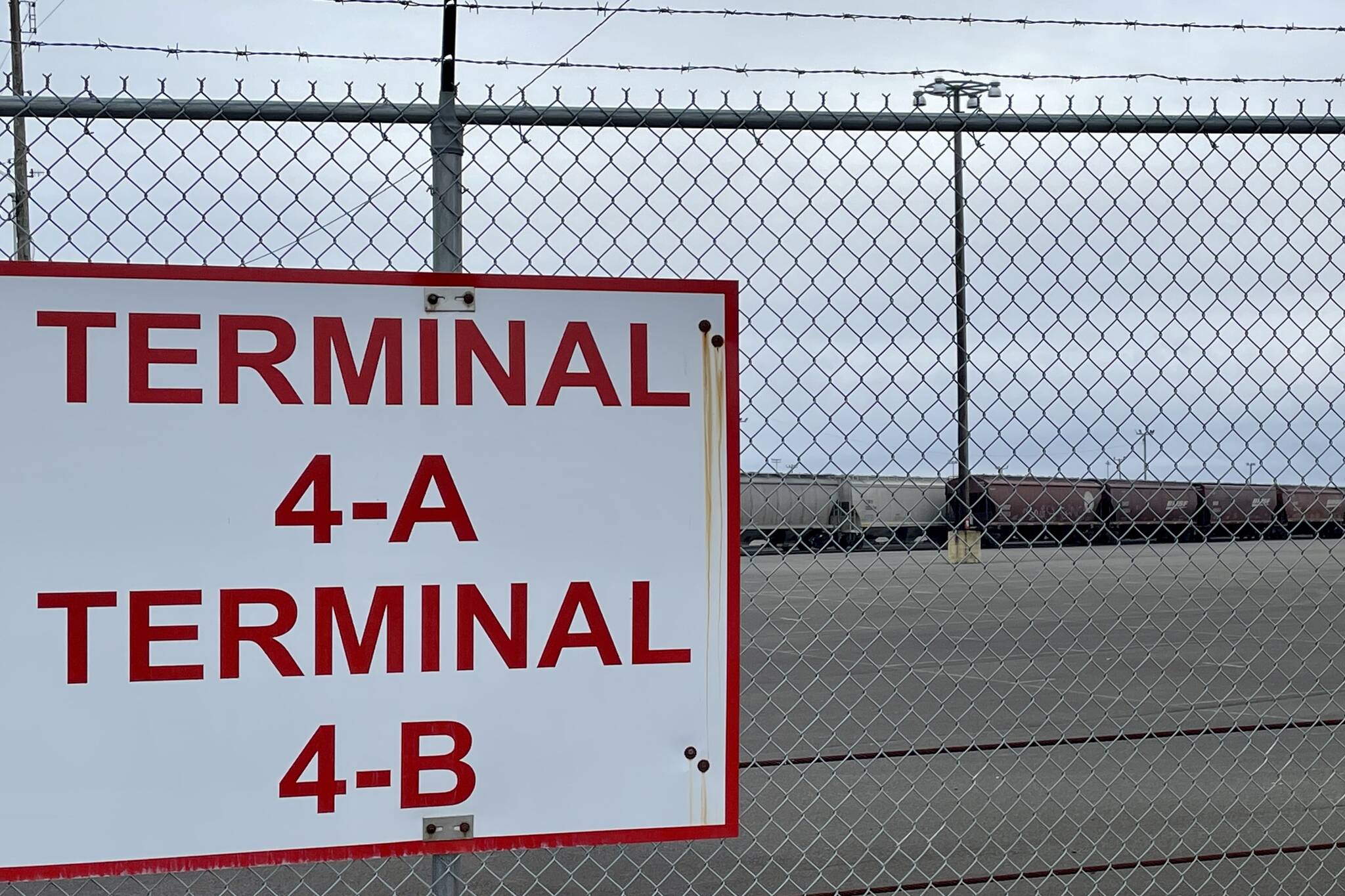

While the western end of the pier, designated T4B, will host AGP’s newly constructed loading infrastructure, the eastern end, T4A, will also be modernized, so that it can serve other clients.

“T4A is a flexible terminal,” Koski said. “It can be things like automobiles, large equipment, logs.”

However, operations at T4B would cut off access to the cargo yards for T4A as it’s currently laid out. This is where the third part of project, redeveloping the casting basin, becomes critical, Koski said.

“It’s been analyzed for its best and highest use for how it could be productive space,” Koski said. “Its best use is to be cargo laydown.”

The casting basin was built and operated by the state from 2011 to 2015 for one purpose: to build the hollow concrete pontoons that would become the floating 520 Bridge between Seattle and Bellevue. The project complete, the port purchased the space, but the site has lain empty and unused until now.

“This one’s relatively simple,” Koski said. “We’re gonna fill the hole. We’re going to use as much of this as possible, this material that’s here for us.”

The fill excavated in the building of the casting basin will be used to refill it, Koski said, and then the area will be leveled and flattened for use as a multi-purpose cargo yard to support T4A.

Funding/process

Nothing good comes for free. In the case of the port expansion, it’s going to require a not-insignificant amount of funding to make it happen. However, much of that will come from grants, Dunlap said, and there are no plans for any new costs to residents.

“AGP has been doing this well here for 20 years,” Dunlap said. “What they’re doing here is looking to duplicate it.”

A $25.5 million Port Infrastructure Development Grant will make up about half of the $47 million in estimated construction costs; a combination of state funding, tax increment financing, and funding from the port itself will make up the other half, according to the news release.

“We’ve been planning for this for a while,” Dunlap said. “As we get toward final design, we’re on the hook for overages.”

The project planners are evaluating possible impacts to the area as part of the process, Dunlap said. All of the results of evaluation will be made publicly available, Dunlap said, and there will be a public comment period as the process moves down its course. With a doubled export capacity, for example, comes twice the amount of rail cars coming through the county.

“The rail traffic is going to increase. We’ve been saying that for a decade,” Dunlap said. “The rail traffic is our lifeline here at the port.”

The earliest metaphorical shovels will hit dirt is spring 2024, according to the port’s schedule.

“We understand this is an aggressive schedule,” Dunlap said. “We’re trying to meet our customer’s timeline and schedule.”

The port expansion will benefit many, and make the Port of Grays Harbor, one of the ports on the West Coast connected to two of the country’s seven Class 1 freight railroads, a more attractive shipping avenue, Dunlap said.

“This wasn’t just for Grays Harbor, this wasn’t just for AGP. This project benefits lots of people,” Dunlap said. “Hundreds of thousands of farmers across the Midwest are going to have their product come through this terminal.”

Contact reporter Michael S. Lockett at 757-621-1197 or mlockett@thedailyworld.com.