By By Amina Khan

Los Angeles Times

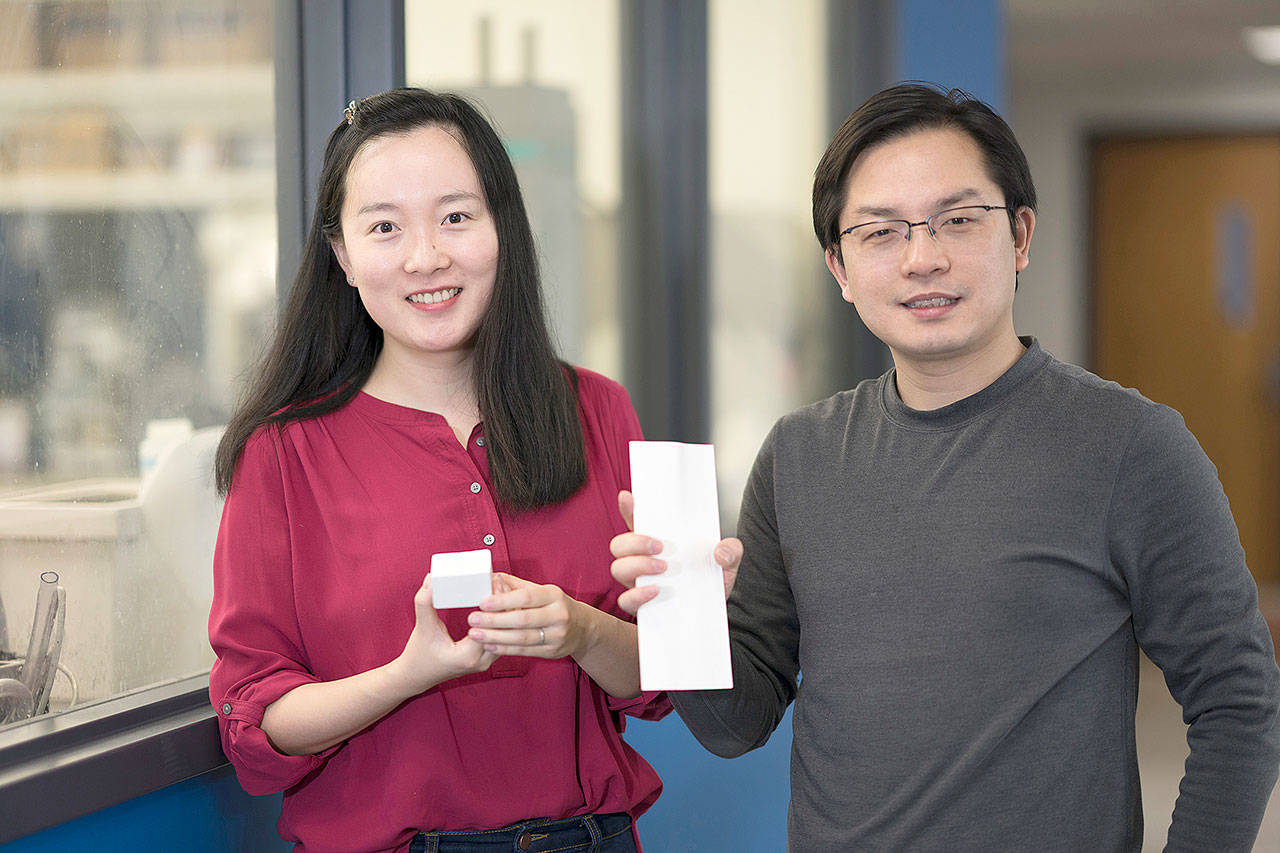

Scientists have designed a heat-insulating material made from wood that is both light and strong and made entirely from tiny, stripped-down wood fibers.

The so-called nanowood, described in the journal Science Advances, could one day be used to make more energy-efficient buildings. It’s cheap and biodegradable, too.

“Nature is producing this kind of material,” said senior author Liangbing Hu, a materials scientist and engineer at the University of Maryland in College Park.

Managing heat is a major issue in the cities we build. It’s hard to keep heat indoors in the winter and keep it outdoors in the summer. The insulating materials currently in use are often very expensive to make, both in terms of money and of energy. They’re not usually biodegradable and ultimately contribute to our growing landfills. So scientists have been trying to come up with cheaper, more environmentally friendly options.

Hu has been probing the properties of nanocellulose, nanometer-scale versions of cellulose, the tough carbohydrate in the cell walls of plants that allows tree trunks to grow strong and tall. At these incredibly small scales, cellulose fibers can take on remarkable characteristics, including a strength-to-weight ratio that’s about eight times that of steel.

Hu and his team have already developed a strong, dense material they called super wood, in part by removing some of the wood’s lignin — a complex polymer that holds cellulose in the wood together, almost like glue — and hemicellulose, another component of woody tissue.

But for this project, Hu and his colleagues removed all of the lignin and most of the hemicellulose. Lignin is very good at conducting heat — which means it would be a terrible insulator. Without all that lignin, the woody material turned pure white, allowing it to reflect incoming light rather than absorb it (which also helps to block heat).

The secret to nanowood’s insulating powers lies partly in its structure. Styrofoam is isotropic: It basically looks the same from any angle. But nanowood is anisotropic: The fibers are bundled together in parallel, so it looks very different from different angles. Heat can travel up and down the fibers with ease, but can’t easily cross them, particularly because of the air gaps left after all the woody filler (lignin and hemicellulose) was removed.

The scientists found that the nanowood was just as good an insulator as Styrofoam — slightly better, even. It far outclassed other materials, too.

On top of that, the nanowood was also lightweight and could withstand pressures of 13 megapascals. That’s about 50 times higher than insulators like cellulose foam and more than 30 times higher than the strongest of the commercially-used thermal insulation materials, they said.

“To the best of our knowledge, the strength of our nanowood represents the highest value among available super insulating materials,” the study authors wrote.

Even better, nanocellulose is readily available and relatively cheap to process, potentially costing as little as $7.44 per square meter. (The key to keeping it sustainable, Hu added, would be to harvest fast-growing trees like balsa, and leave slow-growing trees alone.) In the right conditions, bacteria can eat it, making it biodegradable.

“When the thickness is less than 1 mm, the nanowood slice can be rolled and folded, making it suitable for scenarios that require flexibility, such as pipelines in chemical factories and power plants,” the authors wrote.

Hu said that such a strong, lightweight, thermally insulating biodegradable material could have a host of future uses. It could be used to build skyscrapers, to manufacture cars, even protect heat-sensitive electronics, whether on Earth or in space.